D&C JRCLMM SECTION 220577 FLOOR AND AREA DRAINS SEE

D&C JRCLMM SECTION 220577 FLOOR AND AREA DRAINS SEED&C JRCLMM USE THIS SECTION FOR FIRE PROTECTION WORK

SECTION 15152

D&C JRC:lmm

SECTION 220577

FLOOR AND AREA DRAINS

SEE INFORMATION AFTER END OF SECTION.

PART 1 GENERAL

1.01 REFERENCES

A. Unless otherwise specified, the Work of this section shall meet the applicable requirements of FS WW-P-541 - Plumbing Fixtures, and ASME A112.21.1M - Floor Drains.

1.02 SUBMITTALS

A. Product Data: Catalog sheets, specifications and installation instructions for each type drain specified.

1.03 MAINTENANCE

A. Special Tools: Deliver to the Director’s Representative.

1. Tools for Vandal Resistant Fasteners: One for each type and size.

PART 2 PRODUCTS

SEE INFORMATION AT END OF SECTION REGARDING TYPES OF DRAINS.

2.01 TYPE A FLOOR DRAIN

A. Drain Body: Coated cast iron, two-piece body with reversible flashing clamp, minimum 9 inch dia drainage flange, corrosion resistant bolts, weep holes, bottom outlet, and connection to match piping option selected.

B. Strainer Head: Round, minimum 7 inch dia, nickel bronze with threaded shank for height adjustment.

C. Strainer Grate: Polished nickel bronze, heel proof; secured with stainless steel vandal resistant fasteners.

D. Acceptable Drain Series: Josam 30000A, Smith 2010A, Wade W1100, and Zurn Z415.

2.02 TYPE B FLOOR DRAIN

A. Drain Body: Coated cast iron, two-piece body with reversible flashing clamp, minimum 9 inch dia drainage flange, corrosion resistant bolts, weep holes, bottom outlet, and connection to match piping option selected.

B. Strainer Head: Round, minimum 5 inch dia, nickel bronze with threaded shank for height adjustment.

C. Strainer Grate: Polished nickel bronze, heel proof, fitted with a 4 inch high, 4 inch dia nickel bronze funnel, and secured with stainless steel vandal resistant fasteners.

1. Funnel either cast integral with, threaded or bolted into top of strainer grate.

D. Acceptable Drain Series: Josam 30000E2, Smith 2010A, Wade W1100, and Zurn Z415.

2.03 TYPE C FLOOR DRAIN

A. Drain Body: Coated cast iron, two-piece body with reversible flashing clamp, minimum 9 inch dia drainage flange, corrosion resistant bolts, weep holes, bottom outlet, and connection to match piping option selected.

B. Strainer Head: Round, minimum 5 inch dia, nickel bronze with threaded shank for height adjustment, and 4 inch wide latex bonding flange.

C. Strainer Grate: Polished nickel bronze, heel proof; secured with stainless steel vandal resistant fasteners.

D. Acceptable Drain Series: Smith DX2010A, Wade W1100, and Zurn Z415.

2.04 TYPE D FLOOR DRAIN

A. Drain Body: Coated cast iron, two-piece body with reversible flashing clamp, minimum 9 inch dia drainage flange, corrosion resistant bolts, weep holes, bottom outlet, and connection to match piping option selected.

B. Strainer Head: Round, minimum 5 inch dia, nickel bronze, with threaded shank for height adjustment, and 4 inch wide latex bonding flange.

C. Strainer Grate: Polished nickel bronze, heel proof, fitting with a 4 inch high, 4 inch dia nickel bronze funnel, and secured with stainless steel vandal resistant fasteners.

1. Funnel either cast integral with, threaded or bolted into top of strainer grate.

D. Acceptable Drain Series: Smith DX2010A, Wade W1100, and Zurn Z415.

2.05 TYPE E FLOOR DRAIN

A. Drain Body: Coated cast iron, two-piece body with flashing clamp, minimum 9 inch dia drainage flange, corrosion resistant bolts, weep holes, side outlet, and threaded connection.

B. Strainer Head: Round, minimum 7 inch dia, nickel bronze with threaded shank for height adjustment.

C. Strainer Grate: Polished nickel bronze, heel proof, secured with stainless steel vandal resistant fasteners.

D. Acceptable Drain Series: Josam 30100A, Smith 2015A, Wade W1160, and Zurn Z430.

2.06 TYPE F DRAIN

A. Drain Body: Coated cast iron, two-piece body with flashing clamp, minimum 15 inch dia drainage flange, corrosion resistant bolts, weep holes, bottom outlet, and connection to match piping option selected.

B. Strainer Head: Round, minimum 12 inch dia, coated cast iron, height adjustable.

C. Strainer Grate: Cast iron anti-tilt grate secured with stainless steel vandal resistant fasteners.

D. Acceptable Drain Series: Josam 31200, Smith 2330, Wade W1240, and Zurn Z526.

2.07 TYPE G DRAIN

A. Drain Body: Coated cast iron, deep pattern, two-piece body with flashing clamp, minimum 16 inch dia drainage flange, corrosion resistant bolts, weep holes, bottom outlet, and connection to match piping option selected.

B. Strainer Head: Round, minimum 11 inch dia, coated cast iron, height adjustable.

C. Strainer Grate: Cast iron, loose setting, deep flange tractor grate.

D. Acceptable Drain Series: Josam 31700, Smith 2340, Wade W1240, Zurn Z521.

2.08 TYPE H FLOOR DRAIN

A. Drain Body: Coated cast iron, two-piece body with flashing clamp, minimum 15 inch dia drainage flange, corrosion resistant bolts, weep holes, bottom outlet, and connection to match piping option selected.

B. Strainer Head: Round, minimum 12 inch dia, coated cast iron, height adjustable, with loose setting cast iron sediment bucket.

C. Strainer Grate: Cast iron, loose setting, anti-tilt, deep flange grate.

1. Grate cannot be installed until sediment bucket set in position.

D. Acceptable Drain Series: Josam 31220, Smith 2360, Wade W1240TD, and Zurn Z521.

2.09 TYPE I DRAIN

A. Drain Body: Coated cast iron, deep pattern, two-piece body with flashing clamp, minimum 15 inch dia drainage flange, corrosion resistant bolts, weep holes, bottom outlet, and connection to match piping option selected.

B. Strainer Head: Round, minimum 15 inch dia, coated cast iron, with loose setting cast iron sediment bucket.

C. Strainer Grate: Cast iron, loose setting tractor grate.

1. Grate cannot be installed until the sediment bucket set in position.

D. Acceptable Drain Series: Josam 34620, Smith 2250, Wade W1410, and Zurn Z543.

2.10 TYPE J DRAIN

A. Drain Body: Coated cast iron, two-piece body with flashing clamp, minimum 12 inch dia drainage flange, corrosion resistant bolts, weep holes, bottom outlet, and connection to match piping option selected.

B. Strainer Head: Round, minimum 8 inch dia, coated cast iron, with loose setting cast iron sediment bucket.

C. Strainer Grate: Cast iron, loose setting.

1. Grate cannot be set in place until sediment bucket installed.

D. Acceptable Drain Series: Josam 32120, Smith 2220, Wade W1310-TD, and Zurn Z550Y.

2.11 AREA DRAIN

A. Drain Body: Round, coated cast iron, two-piece body with flashing clamp, minimum 12 inch dia drainage flange, corrosion resistant bolts, weep holes, bottom outlet, and connection to match piping option selected.

B. Strainer Head: Round, minimum 8 inch dia, coated cast iron.

C. Strainer Grate: Cast iron, anti-tilt grate secured with stainless steel vandal resistant fasteners.

D. Acceptable Drain Series: Josam 32100, Smith 2110, Wade W1310, and Zurn Z550.

2.12 FASTENERS

A. Corrosion Resistant Fasteners: Brass, bronze, or Type 302 or 304 or stainless steel bolts.

B. Vandal Resistant Fasteners: Torx head with center pin.

2.13 FREE AREA OF GRATE

A. Minimum strainer grate free area listed below for each connecting pipe size:

|

CONNECTING PIPE SIZE (Inches Nominal) |

INTERIOR DRAINS FREE AREA (Square Inches) |

EXTERIOR DRAINS FREE AREA (Square Inches) |

|

1-1/2 |

3.06 |

4.08 |

|

2 |

4.71 |

6.28 |

|

3 |

10.59 |

14.12 |

|

4 |

18.90 |

25.20 |

|

5 |

29.40 |

39.20 |

|

6 |

42.45 |

56.60 |

|

8 |

75.38 |

100.50 |

PART 3 EXECUTION

3.01 INSTALLATION

A. Install the Work of this section in accordance with the manufacturer’s printed installation instructions, unless otherwise specified.

B. Protect weep holes from plugging during installation. Rod out weep holes after installation to remove obstructions.

USE THE NEXT 2 PARAGRAPHS FOR FLOOR DRAINS INSTALLED IN WATERPROOFED FLOORS.

C. Set drainage flange flush with top of structural floor slab, or at elevation otherwise indicated.

D. After membrane waterproofing installed and cured, secure clamping ring.

E. Adjust strainer head to height indicated. If height not indicated, set at 1/2 inch below finished floor elevation.

F. Secure external components in place with vandal resistant fasteners or devices which cannot be removed without special tools.

END OF SECTION

THE REMAINDER OF THIS DOCUMENT IS FOR INFORMATION ONLY; NOT TO BE INCLUDED IN PROJECT SPECIFICATIONS.

Drain types should be indicated on Drawings (check with Designer). Following schedule briefly describes usage for each drain type.

Type A - General purpose, for use in kitchens, toilet rooms, shower rooms, etc. Foot traffic only.

Type B - General purpose requiring drainage funnel, for use in boiler rooms, kitchens, mechanical rooms,

etc. Foot traffic only.

Type C - General purpose, for use with traffic bearing deck covering.

Type D - General purpose with drainage funnel, for use with traffic bearing deck covering.

Type E - General purpose where side outlet required. Foot traffic only.

Type F - Medium duty.

Type G - Heavy duty.

Type H - Boiler room.

Type I - Garage.

Type J - Trench.

Area Drain - Exterior to building.

END OF INFORMATION

Updated 07/08/09

Printed

Tags: 220577 floor, drains, section, jrclmm, floor, 220577

- LA COSTUMBRE COMO FUENTE DEL DERECHO MARTÍN CALLEJA I

- UNIVERSITY OF TEXAS SCHOOL OF LAW STUDY ABROAD

- CSD 424 [12115] NAME ADDRESS TELEPHONE NO & ID

- RENCONTRES EURO MÉDITERRANÉENNES 2009 DES FORMATIONS SUR LES RISQUES

- LOS LÍMITES DE LA VIDA A) TEXTO DIVULGATIVO LA

- METODOLOXÍAS DOCENTES E METODOLOXÍAS PARA AVALIAR METODOLOXÍAS DOCENTES TIPOLOXÍA

- ATTACHMENT 13 LIST OF REQUIRED REPORTS CONTRACTOR REPORTS

- ADDITIONAL FILE 5 EVALUATION OF QUALITY OF THE INCLUDED

- ASESOR AÑO 2012 N º DE ORDEN ADHESIÓN AL

- A MAGYAR VÍZISÍ ÉS WAKEBOARD SZÖVETSÉG DOPPINGSZABÁLYZATA

- SPEECHLANGUAGEHEARING CENTER FOUNDERS HALL ROOM 1300 CAMPUS BOX 1147

- LA POESÍA ESPAÑOLA DEL S XVI ANTES DE GARCILASO

- Ð ² Ú ² Ê Î ² Ü Æ

- 012 345 SISTEMA PARA INFANTES A TRES AÑOS DE

- BRIEF STORY OF PROPHET MUHAMMAD (PBUH) PRAISE BE TO

- REQUEST FOR CUSTODY REVIEW HEARING CHILD’S NAME CASE

- VERMONT FORENSIC LABORATORY LAB USE ONLY PO BOX 47

- TABLE S1 INTRINSIC LARYNGEAL MUSCLES OF THE DHOLE MUSCLE

- PROYECTO EDUCATIVO DEL INSTITUTO DE LOS HERMANOS DE LA

- CEIP ANITA ARNAO LAS DECISIONES DE CARÁCTER GENERAL SOBRE

- TRANSCRIPTION DE L’EXTRAIT DU JOURNAL TÉLÉVISÉ DE BBC MUNDO

- DISCIPLINARE PER LA GESTIONE E LA MANUTENZIONE DEGLI IMPIANTI

- ANAMNESE ASTMACOPD NAAM + VOORLETTERS ………………………………… LENGTE………………………… GEB

- LAMPIRAN II PERATURAN MENTERI NEGARA LINGKUNGAN HIDUP NOMOR

- 3 APUNTES DE HISTORIA DE ESPAÑA 1 LOS REYES

- ORD Nº 5649369 MATERIA QUIEBRA CONVENIO JUDICIAL PREVENTIVO INDEMNIZACIÓN

- INTRACORONARY ACETYLCHOLINE PROVOCATION IN PATIENTS WITH UNOBSTRUCTED CORONARY ARTERIES

- SUMMARY OF HISTORICAL FIGURES DIRECTIONS LISTED BELOW ARE THE

- ADATVÉDELMI ÉS ADATKEZELÉSI SZABÁLYZAT PEFIDA ALKATRÉSZGYÁRTÓ SZOLGÁLTATÓ ÉS KERESKEDELMI

- APEL ZESPOŁU KEP DS APOSTOLSTWA TRZEŹWOŚCI I OSÓB UZALEŻNIONYCH

IMPROVING THE FUNCTIONAL COMMUNICATION ABILITY OF ADULTS WITH TBI

BENELUXPOLGÁROK MAGYARORSZÁGON DR KEMKERS ROBERT BEVEZETÉS MAGYARORSZÁG EGYRE TÖBB

6 SEJA OBČINSKEGA SVETA GRADIVO K TOČKI 10 PRAVILNIK

6 SEJA OBČINSKEGA SVETA GRADIVO K TOČKI 10 PRAVILNIK SLIDE 1 SLIDE 2 SLIDE 3 SLIDE 4 SLIDE

SLIDE 1 SLIDE 2 SLIDE 3 SLIDE 4 SLIDE 2022_64_343_120_1_ANEXO%203%20ESPECIFICACIONES%20TECNICAS

2022_64_343_120_1_ANEXO%203%20ESPECIFICACIONES%20TECNICAS DYNAPULSE EDUCATION DOC 031308A1 DYNAPULSE CENTRAL AORTIC BLOOD PRESSURE

DYNAPULSE EDUCATION DOC 031308A1 DYNAPULSE CENTRAL AORTIC BLOOD PRESSURE TENDER JOB DESCRIPTION JOB TITLE DROPIN COORDINATOR

TENDER JOB DESCRIPTION JOB TITLE DROPIN COORDINATORINFORMATIONEN ZU HP DESKSCAN II V25 DIESES DOKUMENT ENTHÄLT

DIRULAGUNTZAESKAERA (D01) SOLICITUD DE SUBVENCIÓN (D01) ESKAERA OROKORRA

DIRULAGUNTZAESKAERA (D01) SOLICITUD DE SUBVENCIÓN (D01) ESKAERA OROKORRA  PAGE 22 E NQUIRY FORM CONTACT DETAILS COMPANY TELEFAX

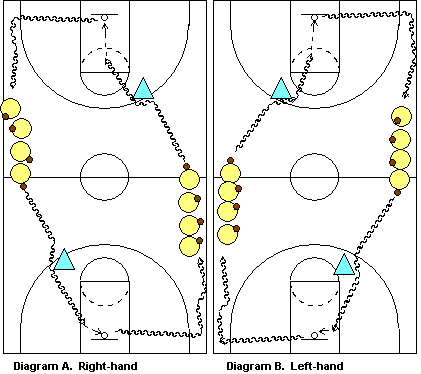

PAGE 22 E NQUIRY FORM CONTACT DETAILS COMPANY TELEFAX DRIBBLING MOVES DRILL COACH’S CLIPBOARD HTTPWWWCOACHESCLIPBOARDNET USE THIS FULLCOURT

DRIBBLING MOVES DRILL COACH’S CLIPBOARD HTTPWWWCOACHESCLIPBOARDNET USE THIS FULLCOURT 6 6 “SOLICITUD PARA LA ELECCIÓN DE CENTROS CURSO

6 6 “SOLICITUD PARA LA ELECCIÓN DE CENTROS CURSOSEAMLESS SUCKERS HAS BEEN AROUND FOR A FEW YEARS

RURAL WATER DISTRICT NO 4 DOUGLAS COUNTY POLICY NO

ACTA DE LA REUNIÓN DE LA COMISIÓN DE DE

JEDNOSTKA ORGANIZACYJNA SPORZĄDZAJĄCA WNIOSEK MIEJSCOWOŚĆ I DATA SPORZĄDZENIA WNIOSKU

JEDNOSTKA ORGANIZACYJNA SPORZĄDZAJĄCA WNIOSEK MIEJSCOWOŚĆ I DATA SPORZĄDZENIA WNIOSKUMODEL ACADEMIC STANDARDS FOR SCHOOL COUNSELING ACADEMIC DOMAIN STANDARD

PHONE (850) 2453200 FAX (850) 2453234 325 WEST GAINES

PHONE (850) 2453200 FAX (850) 2453234 325 WEST GAINESŠTEVILKA 01400012018 DATUM 2932018 ODBOR ZA DRUŽBENE DEJAVNOSTI OBČINSKI

TURNING POINT A STREETCAR NAMED DESIRE QUESTION