DISK BRAKES AND CLUTCHES D D TORQUE CAPACITY UNDER

2 BETTER BRAKES ON HEAVY VEHICLESDISK BRAKES AND CLUTCHES D D TORQUE CAPACITY UNDER

THERE ARE TWO BRAKES ON THE MACHINE ONE IS

Machine Design

Disk Brakes and Clutches

d

D

Torque capacity under “Uniform Wear” condition per friction surface

![]()

Where

f: Coefficient of friction

pa: Maximum pressure on brake pad

d,D: Inner and outer pad diameters

Torque capacity under “uniform pressure” conditions per friction surface

![]()

Maximum clamping forces to develop full torque

For Uniform Wear

![]()

For Uniform Pressure

![]()

Problem #M8

Given: A multi-plate disk clutch

d=0.5”

D=6”

Pmax=100 psi

Coefficient of friction=0.1

Power transmitted= 15 hp at 1500 rpm

Find: Number of friction surfaces

Answer: N=2 (uniform pressure)

N=9 (uniform wear)

Energy Dissipation in Clutches and Brakes

The time it takes for two rotational inertia to reach the same speed after engagement through a clutch is:

I2

I1

![]()

where

T: Common transmitted torque

: angular speed in rad/sec

The total energy dissipated during clutching (braking) is:

![]()

If the answer is needed in BTU, divide the energy in in-lb by 9336.

Problem #M9: A brake with braking torque capacity of 230 ft-lb brings a rotational inertia I1 to rest from 1800 rpm in 8 seconds. Determine the rotational inertia. Also, determine the energy dissipated by the brake.

Solution hints:

Convert rpm to rad/sec: 1 = 188 rad/sec

Note that 2=0

Find the ratio (I1I2/I1+I2) using time and torque=>9.79

Note that I2 is infinitely large => I1=9.79 slugs-ft

Find energy from equation=>173000 ft-lb

Springs

Coverage:

Helical compression springs in static loading

Terminology:

d: Wire diameter

D: Mean coil diameter

C: Spring index (D/d)

Nt: Total # of coils

N: Number of active coils

p: Coil pitch

Lf: Free length = N*p

Ls: Solid length

La: Assembled length

Lm: Minimum working length

Spring Rate of Helical Springs (compression/extension)

![]()

where : N is the number of active coils

Plain ends: N=Nt

Plain and ground ends: N=Nt-1

Square ends: N=Nt-2

Square and ground ends: N=Nt-2

G: shear modulus = E/2(1+)

G=11.5*106 psi for steels

Shear stress in helical springs for static loading

![]()

where

![]() and C is the spring index.

and C is the spring index.

Shear strength in springs

![]() Ferrous

without presetting

Ferrous

without presetting

![]() Ferrous

with presetting

Ferrous

with presetting

Solid Lengths

Ls=(Nt+1)d with plain ends

Ls=(Nt)d with ground ends

Spring Surge Frequency

![]()

Where g is the gravitational acceleration and Wa is the weight of the active coils:

![]()

with being the specific gravity of spring material. For steel springs when d and D are in inches:

![]()

Example #M10: Consider a helical compression spring with the following information (not all are necessarily needed):

Ends: Squared and ground

Spring is not preset

Material: Music wire (steel) with Sut=283 ksi

d=.055 inches and D=0.48 inches

Lf=1.36 inches and Nt=10

Find the following. Answers are given in parentheses.

Spring constant, K (14.87 lb/in)

Length at minimum working load of 5 lbs (1.02”)

Length at maximum load of 10 lbs (0.69”)

Solid length (0.55”)

Load corresponding to solid length (12.04 lbs)

Clash allowance (0.137”)

Shear stress at solid length (77676 psi)

Surge frequency of the spring (415 Hz)

Design of Welds

Welds in parallel loading and transverse loading

Weld Geometry

Throat: t

Leg

: w

Analysis Convention

Critical stresses are due to shear stresses in throat area of the weld in both parallel and transverse loading.

For convex welds, t=0.707w is used.

Yield strength of weld rods used in analysis is 12 ksi smaller than their nominal minimum yield strength.

Analysis Methodology

Under combined loading, different stresses per unit leg length are calculated and combined as vectors.

Stresses based on weld leg (w)

Direct tension/compression:

Direct shear:

Bending:

![]()

Torsion:

![]()

Formulas for Aw, Sw, and Jw are attached for different weld shapes.

Problem M11a -Welds subject to direct shear: Two steel plates welded and are under a direct shear load P. The weld length is 3 inches on each side of the plate and the weld leg is 0.375 inches. What maximum load can be applied if the factor of safety is 2 against yielding? The weld material is E60 with a yield strength of 60 ksi nominal.

Solution (of M11a): From Table:

Aw = 2d = 6

![]()

The design strength of the weld material in shear is:

Sys=.58 Sy = .58(60-12) = 48*.58 = 27.84 ksi

Using a factor of safety of 2, the allowable shear stress is:

Sys,a = 27.84/2 = 13.92 ksi

Equating stress and strength

.6284F = 13920 F=22150 lbs

Problem #M11b – Welds subject to torsion: A round steel bar is welded to a rigid surface with a ¼ “ fillet weld all around. The bar’s outer diameter is 4.5”. Determine the critical shear stresses in the weld when the bar is subjected to a 20,000 lb-in pure torque.

![]()

![]()

Problem #M11c – Welds subject to bending: Solve the previous problem with a bending moment of 35000 lb-in acting on the welds instead of the torsion load.

![]()

![]()

Problem #M11d – Welds subject to combined loads: If the design shear strength (Sys) in the weld is 27800 psi, what is the factor of safety against yielding when both stresses in previous two problems are acting on the bar.

![]()

FS = 27800/12948=2.15

Tags: brakes and, and brakes, under, brakes, capacity, torque, clutches

- CIRCULO EDUCATIVO NOMBRO Y APRENDO LOS DÍAS DE

- CONNECT 4 LOGO ALKUPERÄINEN CONNECT 4 PELI AGEPLAYER LOGO

- POZIV ZA GLAVNU SKUPŠTINU TEMELJEM ČLANKA 277 STAVAK

- fen Bi̇li̇mleri̇ Ensti̇tüsü Müdürlüğü’ne Enstitünüz ……………………… Anabilim Dalı Yüksek

- 14 DANIEL PUEMAPE POSTIGO EL FACTORING EN EL PERU

- ALLEGATO A3 ALLEGATO N 43 AL DLGS 1182011 PRINCIPIO

- CBA CONCLUSION (SECTION4) NAME CORE MY CONFLICT IS…… THE

- SAP MATA KULIAH DU111210 | PENDIDIKAN AGAMA KATOLIK |

- DEN NORSKE KIRKE NES KIRKELIGE FELLESRÅD FINNES OGSÅ

- INTROVERHAALTJES – DROEVIGE GEHEIMEN EERSTE DROEVIGE GEHEIM JEZUS BIDT

- STEPS TO START AND SHUT DOWN A COMPUTER START

- Ondokuz%20May%C4%B1s%20%C3%9Cniversitesi_Farabi%20Protokol%C3%BC%20ve%20B%C3%B6l%C3%BCmler_%202018

- ROLE VOLUNTEER RESTORATIVE JUSTICE FACILITATOR REPORTS TO RESTORATIVE JUSTICE

- ügy Típusa Rendkívüli Települési Támogatás Jogszabály a Szociális

- Palotás Község Önkormányzata 2012május Havi Ülésére Előterjeszteni Tervezett

- NATURE AND SCIENCE 20097(9) NWOYE ET AL MODEL FOR

- 7 TEMA PALŪKANŲ NORMOS IR OBLIGACIJOS 20211101 2 PSL

- CLASSICAL STUDIES NATIONAL 5 RESOURCE SHEET CANDIDATE NAME SCOTTISH

- CRITERIOS DIAGNÓSTICO PARA POLICITEMIA VERA (PV) CRITERIOS PVSG (POLYCYTHEMIA

- Bekölce Község Önkormányzata 112009 (viii 20) Önkormányzatai Rendelete

- EXHIBIT C SUPERIOR COURT OF WASHINGTON COUNTY OF

- GOD KOMMUNAL SERVICE I MARIAGERFJORD KOMMUNE BYRÅDSSEKRETARIATET NORDRE KAJGADE

- SENIN 23 MARET 2020 PSI PERKEMB 1 TUGAS PERTEMUAN

- APSTIPRINĀTS ALŪKSNES UN APES NOVADA FONDA 2016 GADA 29

- PŘÍLOHA Č1 INFORMACE K FINANČNÍMU VYPOŘÁDÁNÍ DOTACE NA ČINNOSTI

- ENFOQUE ECOCRÍTICO DE LA POESÍA DE MANUEL J CASTILLA

- PROJEKAT “OSNAŽIVANJE MLADIH ROMSKIH PORODICA” BROJ DATUM BIZNIS PLAN

- ZAŁĄCZNIK NR 4 SZCZEGÓŁOWY OPIS PRZEDMIOTU ZAMÓWIENIA LP

- KEPADA YTH DEKAN FAKULTAS ADAB DAN HUMANIORA UIN RADEN

- SEND COMPLETED FORM BY EMAIL TO FOUNDATIONISPRSORG OR BY

DOCKLANDS LTD APPLICATION FOR EMPLOYMENT CONSULTANT ACCOUNTANTS –

DOCKLANDS LTD APPLICATION FOR EMPLOYMENT CONSULTANT ACCOUNTANTS – PROJEKTAS MANO VARDAS VANDENS LAŠELIS“ PAKRUOJO R LINKUVOS LOPŠELIODARŽELIO

PROJEKTAS MANO VARDAS VANDENS LAŠELIS“ PAKRUOJO R LINKUVOS LOPŠELIODARŽELIONAMEADDRESSEMERGENCY CONTACT FORM (REVISED 1105) NOTE PLEASE CHECK

IZJAVA MINISTRA ZA OKOLJE IN PROSTOR PO PODPISU KONZORCIALNE

CAMBRIDGE UNIVERSITY PRESS TOP COURSE BOOKS 1 AMERICAN ENGLISH

Ðïࡱáþÿ ¥áeð¿©bjbjx83æx83æ(üáx8cáx8cx9dbÿÿÿÿÿÿx88lllllllx80äëäëäë8üë Ìx9c x80«¦¼õ p Þäåäënö^ââô1{0«âéìüféâx80\x80x80déäë2á¸x80x80äëwybory do Sejmu Rzeczypospolitej

¿CÓMO SE HACE LA TRADUCCIÓN JURÍDICA? ROBERTO MAYORAL ASENSIO

ST NICHOLAS CATHOLIC HIGH SCHOOL GREENBANK LANE HARTFORD NORTHWICH

ST NICHOLAS CATHOLIC HIGH SCHOOL GREENBANK LANE HARTFORD NORTHWICHAANVRAAGFORMULIER ERKENNING INZAKE VERPLICHT PEONDERWERP 2019 TRAINING ‘FRAUDE’ DIT

OUTLIERS LEVERAGE & INFLUENTIAL POINTS IN REGRESSION A FAMOUS

OUTLIERS LEVERAGE & INFLUENTIAL POINTS IN REGRESSION A FAMOUS CDP ITÁLICA ESCUELA DE VERANO DATOS DEL ALUMNO N

CDP ITÁLICA ESCUELA DE VERANO DATOS DEL ALUMNO NJULY 6 2006 NEW MFD PRINTER ALERT CODES PAGE

CONVOCATÒRIA A LA SESSIÓ PLENÀRIA ORDINÀRIA A CELEBRAR EL

CONVOCATÒRIA A LA SESSIÓ PLENÀRIA ORDINÀRIA A CELEBRAR EL HIGHCLARE SCHOOL MONITORING OF STAFF ETHNICITY FOR THE PURPOSE

HIGHCLARE SCHOOL MONITORING OF STAFF ETHNICITY FOR THE PURPOSE MANUAL DE INSTRUCCIONES DE JUSTIFICACIÓN DE AYUDAS PARA EL

MANUAL DE INSTRUCCIONES DE JUSTIFICACIÓN DE AYUDAS PARA ELSVEUČILIŠTE U ZAGREBU FILOZOFSKI FAKULTET IVANA LUČIĆA 3 10000

GROUP 9500 INSTITUTO CANARIO DE DESARROLLO CULTURALSA C LEÓN

GROUP 9500 INSTITUTO CANARIO DE DESARROLLO CULTURALSA C LEÓN NEWS RELEASE FOR MORE INFORMATION JULIE FRITSCH NAAE COMMUNICATIONSMARKETING

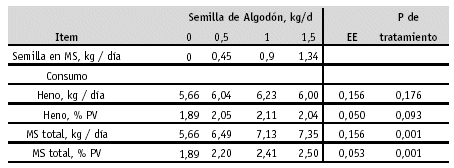

NEWS RELEASE FOR MORE INFORMATION JULIE FRITSCH NAAE COMMUNICATIONSMARKETING 6 UTILIZACIÓN DE LA SEMILLA DE ALGODÓN EN LA

6 UTILIZACIÓN DE LA SEMILLA DE ALGODÓN EN LA NORMATIVA PARA LA REALIZACIÓN DE ACTIVIDADES COMPLEMENTARIAS Y EXTRACURRICULARES

NORMATIVA PARA LA REALIZACIÓN DE ACTIVIDADES COMPLEMENTARIAS Y EXTRACURRICULARES