PRINCIPLES OF SUPPLY CHAIN MANAGEMENT FOR DISASTER RELIEF OPERATIONS

2007SOM3012ATTB1REV1 AGENDA ITEM V COMPLEMENTARY ANTICORRUPTION PRINCIPLES FOR2007SOM3012ATTB3REV1 AGENDA ITEM V CONDUCT PRINCIPLES FOR PUBLIC

OUTLINE FIRST PRINCIPLES BASELINE REVIEW DEPARTMENT

SEASON TICKET LOANS CONTENTS POLICY STATEMENT 1PRINCIPLES

WORKSHOP MOLECULAR PHOTOREACTIVITY ON METALOXIDE SURFACES FROM FIRSTPRINCIPLES

0 APEC SUBCOMMITTEE ON STANDARDS AND CONFORMANCE PRINCIPLES

Principles of Supply Chain Management for Disaster Relief Operations

Principles of Supply Chain Management for Disaster Relief Operations

I Nyoman Pujawan, Nani Kurniati, Naning A. Wessiani, Putu D. Karningsih,

Arief Rahman, Nugroho P. Negoro

Department of Industrial Engineering, Sepuluh Nopember Institute of Technology, Surabaya 60111, Indonesia

E-mail: pujawan@ie.its.ac.id

Abstract

Supply chain management has been widely researched and applied in business context. Recently, there is an increasing concern toward the management of logistics/supply chain for disaster relief operations (DRO). While some aspects of commercial logistics/supply chain, such as coordination, collaboration, and information visibility are applicable for disaster relief operations, many are not directly transferable. Based on review of current relevant literature, we propose a number of underlying principles of supply chain management for disaster relief operations. The principles will then be applied as a benchmark to evaluate the logistics/supply chain management of a disaster relief operations recently happening in one area of East Java, Indonesia. The results suggest that most of those principles are far from being well applied.

Keywords: Disaster relief operations, logistics, supply chain

Introduction

There has been an increasing demand for humanitarian relief operations in line with more and more disaster happening around us. The International Federation of Red Cross and Red Crescent Societies (2005) suggested that the number of disaster in the period of 1999 – 2003 has increased to about 707 and affected about 213 millions people annually. In 2004, we all witnessed the Tsunami, one of the most tragic natural disasters in the history of human life, which killed about 165,708 people, affected more than 530,000 people, and resulted in economic losses of about US$4,451,600,000. Unfortunately, due to environmental degradation, the spread of HIV/AIDS in the developing countries, and rapid urbanization, the number of disaster, both natural and man made, is expected to increase by five-fold in the next fifty years (Thomas, 2005).

One of the most important issues in disaster relief operations has been the logistics / supply chain activities. In a DRO, supply chain / logistics activities are aimed at responsively and cost-effectively matching demand and supply of goods such as foods, shelter, tents, and medicine. Logistics in DRO context include such activities as assessing demand, procuring goods, receiving, sorting, storing, tracing and tracking deliveries, and determining priorities. In every relief operations, supplies came from everywhere, domestically and/or internationally. Generally, the main problem has not been in the amount of supplies available, but in the distribution of food, shelter, tents, and other goods quickly and in sufficient quantity to the people in need. After the Tsunami attacked several Asian regions in December 2004, the overwhelmed of goods arrived at the airports exceeded the capacity of the aid agencies in the field to sort, store, and deliver goods effectively (Thomas, 2005).

In spite of the importance of its role in ensuring the smooth flow of goods from the origin to the destination, logistics / supply chain has always received insufficient attention during the disaster relief operations. The recognition of logistics profession among the aid agencies seems to be relatively low. On the academic side, the development of supply chain / logistics management concepts, theories, tools, and principles is still in the infancy stage, by far lagging behind those for commercial / business sectors. In this paper, we propose a number of principles for logistics / supply chain management of the disaster relief operations. Such principles are important as general guidelines for those handling logistic / supply chain operations for DRO. A case study will be presented and evaluated based on the proposed principles.

Logistics / Supply Chain Management: Moving from Business to DRO

There is no doubt that Supply Chain Management has been the key for creating competitiveness in most commercial organizations. The roles of supply chain management in making companies like Wal-Mart, Dell, and P & G so competitive in the market is well acknowledged. With excellent supply chain management, commercial organizations are able to produce and deliver materials / products from the point of origin to the point of consumption in a cost effective way. The underlying principles behind supply chain management have been the integration among functions within each organization as well as collaboration and information sharing among organizations within the supply chain. Wal-Mart and P & G, for example, have long enjoyed the power of collaboration and information sharing between them. The relationship which was initially characterized by adversarial, fragmented processes, and obsessed by day-to-day transactions, has been transformed into more collaborative relationship which includes the use of joint scorecards and measurements, driving out costs through automation, and sharing data to better understand the consumers (Grean and Shaw, 2000).

Both commercial and DRO supply chains are similar in a number of ways so that some of the underlying principles, approaches, and techniques developed for commercial / business supply chain management can be applied for disaster relief operations. In general, both DRO and commercial supply chain share the following common characteristics:

Both aims at effective delivery of goods from the source to the point of demand

In both cases, supply network could be very complex, involving multiple parties of both domestic as well as international organizations, structured in a multi-echelon or multi-tiered system.

In both cases, demand is normally uncertain and effort is needed to predict the level of demand.

Visibility and coordination is required in both cases to improve the responsiveness and cost-effectiveness of the supply chain operations.

On the other hand, there exist many differences between the two. Such differences suggest that many of the concepts and techniques in commercial logistics / supply chain are not directly transferable to disaster relief operations. Adjustments of the existing concepts and techniques as well as developments of the new ones are necessary, hence challenges and opportunities for academic community. The differences span from the number of parties involved, the configuration of the supply network, the pattern and uncertainty of demand, and the pattern and uncertainty of supply, each of them is detailed below:

Parties involved. In a commercial supply chain, those parties are relatively well linked each other. Many of the relationships are long-term, developed based on partnerships principles. In DRO, most of the relationships are developed instantaneously during the relief operations. The way parties involved are totally different. In a commercial supply chain, parties are engaged in supply chain activities following a proper assessment of each other’s values and formalized into contracts. For example, a vendor will be able to supply parts or materials after it is evaluated and approved by a manufacturer. In a DRO supply chain, many parties are unknown and voluntary, no evaluation is needed to enable them participating in a relief operations. Individuals, social, business, and government organizations could easily be engaged in the relief operations as a volunteer or a donor (supplier) of foods, shelters, tents, medicines, and other supplies.

Network configuration. In a commercial supply chain, a network is normally composed of multiple supply sources to cover demand in many different locations. The total demand is the aggregation of demands from regional markets. Configuration is relatively stable, although changes could happen through switching of suppliers, consolidation of manufacturing facilities, and changes in distribution networks. A DRO supply chain, in contrast, has only one demand point and fulfilled from multiple sources of supply. Configuration is unstable and many suppliers only supply once during the relief operations. Figure 1 illustrates the difference between network configuration of a commercial and a DRO supply chain.

Demand. A commercial supply chain exists because there is a sufficient demand to economically justify the supply chain existence. Although the demand for a particular product could be quite small and quickly disappear due to rapid development of new products, the whole demand is normally quite stable, large and sustainable for a relatively long time. In most situations, past data can be used to forecast the level of demand, although causal relationships are often needed on top of the sales history. Standard techniques to forecast demand are available. In DRO, demand is short-term in nature, very unstable with time, and no past data can be used to assess the level of demand. Knowledge from other disasters could be useful, but quick assessment at the field is more important to predict demand. No standard technique is available to forecast demand.

Supply. Supply of materials, components, or products in a commercial supply chain comes from predetermined suppliers. The level of supply activity reflects the level of demand, although some discrepancies exist due to forecast errors. Suppliers normally react in response to customer orders. The performance of suppliers is maintained through proper selection and performance monitoring (vendor rating). On the other hand, there is no certified supplier in the DRO supply chain. Supplies come as a result of appeal from news media or aid agencies involved in relief operations. In most cases, the suppliers / donors perception and ability determines the types and quantity of items supplied by donors or aid agencies.

Demand

Demand

Supply Supply

Supply

Demand

Supply

Demand

Supply

Intermd.

channel

Supply

Supply

Demand

Supply

Demand

Demand

Figure 1 Illustration of the difference in the supply – demand area for commercial and DRO supply chain

Principles of SCM for DRO

Differences in the characteristics of commercial and DRO supply chain require different ways and different focus of managing them. While logistics activities for commercial and business organizations are aimed at achieving competitive advantage in the market through one or a combination of advantages in cost, quality, speed, or responsiveness, the DRO supply chain is aimed at reducing fatality (loss of life) and alleviate suffering (Thomas, 2003; Beamon, 2004). Obviously, similarity exists between the two, and thus there are common principles that apply to both commercial and DRO supply chains, but the specificity of each general principle could be quite different for the two areas. In this section, the following principles for managing DRO supply chain are proposed. How they are adapted to DRO supply chain is discussed:

Information visibility

Coordination

Accountability

Professionalism

Visibility

Visibility has been one of the most important words in the field of supply chain management. Supply chain visibility is associated with an ability to see what is happening beyond the four walls of the organization. With greater visibility within the supply chain, a manufacturing company would be able to: trace the status of an order placed to its supplier, obtain real demand from the end customers through POS data, and monitor stock level of its products in the retailers and distributors. Such a visibility is attainable if partners within the supply chain are willing to share information and there are infrastructures or technology in place to quickly and accurately do so. Visibility has helped commercial supply chain to improve efficiency and service level as well as to speed up responses to customers. Likewise, in the defense sector, visibility is also a critical issue. In the Department of Defense (DOD) of the USA, visibility is achieved through automatic identification for each item in inventory (Engels, et al, 2004) so that it is possible to track the quantity available and the stock position for each item. For military purposes, it is extremely important to use such technology as automatic identification so that accurate movements of items from suppliers to the front line can be traced. With high visibility, a logistic officer, for instance, will be able to obtain detailed information about what is inside a container and when the container is expected to arrive in a port so that appropriate anticipation can be made related to unloading of the container.

Similar to commercial and military logistics / supply chain, visibility is vital to the effective operations of a disaster relief supply chain. Visibility in DRO means that critical information is accessible by interested parties. More specifically, logistics operators in the field know what items are available, the quantity on hand, the expected days of supply, and the location (where they are stored). Such information should be easily updated and accessible not only to logistics people in the field, but also to other interested parties, including aid agencies, major donors, and news media. Visibility also means that major supplies in transit from donors / aid agencies are known. With high visibility, logistics people in the field as well as prospective donors would be able to determine which types of items have sufficient supplies and which items are in shortage. In making procurement plans and appeals, high visibility enables logistics people to account for goods in transit from major donors / aid organizations.

Coordination

In commercial context, a supply chain consists of a number of independent organizations whose primary objectives are often in conflict. Yet, those organizations should work together to achieve chain-wide competitiveness and thus, coordination among them is necessary. According to Xu and Beamon (2006), coordination exists as a strategic response to interdependencies between organizations within the chain. Coordination in a supply chain could be in terms of incentive alignment between conflicting parties (Cachon, 2003), synchronization between production and transportation or delivery schedules (Chandra & Fisher, 1994; Goyal & Nebebe, 2000; Pujawan & Kingsman, 2002), centralization of control such as inventory pooling into a central warehouse (Abdul-Jalbar, 2003); and coordination of production planning for multi-site plants (Bhatnagar and Chandra, 1993; Nigro et al, 2005).

Due to multiple parties involved in DRO supply chains, conflicting objectives are unavoidable. Although ideally all parties involved are directed toward single point of control, such a situation is often disturbed by the lack of trust among participating organizations. Quite often, international aid agencies are unwilling to let local authorities take control of the logistics supply chain activities due to lack of perceived transparency and accountability. Moreover, when competing organizations – such as national or local political parties - involve in the relief process, coordination between them could be very difficult.

The costs of lack of coordination in DRO supply chain could be enormous. Excess of supply for some types of goods, shortages on other types, duplication of efforts, are examples of the outcomes from lack of coordination. Many people working for humanitarian logistics do not know what their counterparts are doing and hence, there was little collaboration and resource sharing. Duplication and low resource utilization could happen in many supply chain decisions, including warehousing, transportation, procurement decisions, etc. As summarized by Thomas and Kopczak (2005), “….. we found that several of them were thinking of deploying a regional warehouse structure for faster response. Coincidently, three were actually talking with warehouse providers in the same city. Similarly, two others had commissioned expensive analyses to select a fleet management system and three were wrestling with the idea of a training program for field logisticians. …….”.

Coordination in a DRO supply chain requires even stronger leadership than that for the commercial sector to bring participating organizations to move toward the same direction. In addition, visibility of information would be of much help in creating a better supply chain coordination. Misunderstanding and debates could be minimized if each of them looks at the same data / information.

Professionalism

Professionalism is related to availability of well trained people to perform the tasks and standard operating procedure to follow. In commercial supply chain, most people working in the logistics / supply chain field are equipped with appropriate trainings. Supply chain body of knowledge and operating procedures for commercial organizations has been developed for decades. In contrast, development of supply chain management for DRO is still in its infancy stage and as a result, very few people involve in the relief operations have appropriate logistics / supply chain management trainings. As Thomas and Kopczak (2005) suggest, people working in humanitarian relief operations came from various backgrounds and they improve their qualifications by experience.

Lack of professionalism leads to lack of recognition and vice versa. To many aid organizations, logistics / supply chain management is just a support function. The difficulty in promoting professionalism in logistics / supply chain of DRO is also attributable to fact that the turnover rate of people working in relief projects is high. High turnover rate, coupled with lack of institutional learning, makes it difficult for aid organizations to deploy well-trained and experienced logisticians to the field.

Professionalism also means that sufficient standard operating procedures are available and they were complied during the relief operations. Fairness principle is also an important element of professionalism. Aid agencies and government authorities must maintain the principles of equality and impartiality in delivering aides to people in need. Such a principle is less important for commercial supply chains.

Accountability

The number of parties directly involved in a DRO process could be very large, ranging from well established international aid agencies to local authority to individuals acting as volunteers. In addition, there are so many other organizations and individuals who indirectly involve as donors, contributing goods, money, facilities, etc. Obviously, those donors are in great interest to know that their contributions reach those in need appropriately and none is misused. Accountability is very important and significant effort is needed to ensure that every contribution is distributed properly and reported transparently. In a major DRO where hundreds of organizations involve in the field and ten of thousands of organizations and individuals contribute as donors, it is very difficult to trace how each of those contribution is used to alleviate sufferings. In commercial supply chains, accountability can be maintained more easily. In addition to annual financial audit, accountability is maintained through standard and controlled business processes. The use of ERP and web-based supply chain in commercial sectors make it easier to record and trace any transaction.

Case Study

On the 31 December 2005, the happy mood of New Year celebration was disturbed by sad news from Jember, a district in East Java, Indonesia. A heavy landslide and flooding were causing massive destruction to local residential and agricultural area in the slope of Mount Argopuro. The deforestation and illegal lodging were blamed to be the major cause of the disaster. The disaster caused about 90 deaths and ruined thousands of homes, destroyed roads, schools, and other public facilities. Thousands of people were homeless and temporarily housed by the Government as refugees. Local authority, who was responsible for the relief operations, said that there were over 7600 refugees at the beginning.

Soon after the disaster, news media, government agencies, political parties, NGOs, and other organizations were quickly involved in collecting foods, shelters, tents, and money to be delivered to people in need. In the first few days, we often heard from the news media about various logistical problems in field. The problem was not in the availability of foods and shelters, but in the way those goods were distributed. In Indonesia, there is a government authority that is responsible for the relief operations. Such an authority is tiered according to the hierarchy of the government organizations; called Bakornas at the national level, Satkorlak at the province level, and Satlak for each district.

On the 2nd and 3rd February of 2006, we visited the suffered area and interviewed five of the organizations involved in the relief area. The five organizations were Satlak of the District of Jember, local military officers assigned to help with the relief operations, and three political parties. Our aim was to focus on how logistics operations were handled. Our findings are summarized in Table 1, following the four general principles proposed above.

Table 1 Summary of results from the case study

|

Aspect |

Our Observation |

|

Information visibility |

Very low information visibility. Most of the organizations involved in the relief operations were struggling to handle the logistics operations manually or at most using a simple spreadsheet application. Information on inventory level is not shared among organizations in the relief operations. Such information is also virtually inaccessible by the public / potential donors. As a consequence, donors deliver goods arbitrarily and this leads to imbalanced availability of goods in the field. For example, during our visit we found that there were a large excess of noodles and used clothes, while shortages on other types of goods. The relief organizations did not have any systematical way to make the inventory level more balanced, but they were passively recording inventory transactions. |

|

Coordination |

Coordination was very limited. The local authority responsible for the relief operations (Satlak), was unable to effectively act as a coordinator. We found over 20 posts for relief centers operated by political parties or independent organizations that did their own operations without proper coordination from Satlak. There was no coordination meeting involving all organizations in the field. As a consequence, there was much duplication of efforts. The interviewee suggested that it was very likely that some people received multiple aides, while others did not receive sufficient amount. |

|

Professionalism |

None of the organizations interviewed in the field had a logistician in their team. Logistics activities were managed by a team member with no prior training or experience on logistics management. There was virtually no procedure or rule applied to receiving, storing, and distributing goods. We also learned from the interview that there was no mechanism or standard operating procedure in place to identify who really were entitled to receive foods, shelter, etc and who were not. A number of organizations explained that it was difficult to distinguish between who really entitled to receive aides and who did not. In some cases, ordinary residents, not affected by the disaster, falsely reported themselves being victims of the disaster and asked for food, shelter, etc. |

|

Accountability |

Transparency in the allocation of goods and money varies, depending on the organizations managed those processes. The Satlak provided us with the summary of goods received and distributed to the refugees as well as the general summary of the cash flow. They also have a web site where we can see the cash flow from January to Mid of March 2006. We did not have any of such figures from other organizations involved in the relief operations. |

Concluding Remarks

Unlike commercial supply chains, the body of knowledge for the disaster relief supply chains is still in the infancy stage. Much needs to be done to advance knowledge and practice of supply chain management for DRO. This paper contributes to the field DRO supply chain by presenting four necessary principles which include information visibility, coordination, professionalism, and accountability. A case study was also presented and discussed based on the above principles. We learned from the case study that much needs to be improved in the logistics aspect of the disaster relief operations. All of the principles did not seem to be well implemented by those involved in the relief operations.

There are a number of possible extensions to this study. First is the development of more detailed process audit, based on the principles proposed in this study, to evaluate logistics management of a DRO. Second, information visibility can be improved if appropriate logistics application for DRO is available and hence development of appropriate applications is necessary. Finally, these principles maybe extended to formulate best practices in supply chain management of disaster relief operations. Finally, we believe that comparison of this case with other cases would improve our understanding on the logistical / supply chain aspects of disaster relief operations.

References

Abdul-Jalbar, B., Gutiérrez, J., Puerto, J. and Sicilia, J. (2003) Policies for inventory /distribution systems: The effect of centralization vs. decentralization, International Journal of Production Economics, 81-82, pp. 281-293

Beamon, B. M. (2004). Humanitarian Relief Chains: Issues and Challenges, The 34th International Conference on Computers and Industrial Engineering, November 14-16, San Francisco, CA

Beamon, B. M. and Kotleba, S. A. (2006). Inventory Modeling for Complex Emergencies in Humanitarian Relief Operations. International Journal of Logistics: Research and Applications, 9 (1), pp. 1-18

Bhatnagar, R. and Chandra, P. (1993). Models for multi-plant coordination. European Journal of Operational Research, 67, pp.141-160

Cachon, G. (2003). Supply chain coordination with contracts. Handbooks in Operations Research and Management Science: Supply Chain Management. edited by Steven Graves and Ton de Kok. North Holland.

Chandra, P. and Fisher, M.L. (1994), Coordination of production and distribution planning, European Journal of Operational Research 72, 503 – 517.

Engels, D. W., Koh, R., Lai, E. M., and Schuster, E. W. (2004). Improving visibility in the DOD supply chain. Army Logistician, May – June

(http://www.findarticles.com/p/articles/mi_m0PAI/is_3_36/ai_n6129799)

Goyal, S. K. and Nebebe, F. (2000). Determination of economic production shipment policy for a single vendor single buyer system. European Journal of Operational Research 121, pp. 175 – 178.

Grean, M., and Shaw, M. J. (2000). Suply-Chain Integration through Information Sharing: Channel Partnership between Wal-Mart and Procter & Gamble, Center for IT and e-Business Management, University of Illinois at Urbana-Champaign, URL: http://citebm.cba.uiuc.edu/IT-cases/Graen-Shaw-PG.pdf

International Federation of Red Cross and Red Crescent Societies (http://www.ifrc.org)

Lo Nigro, G; Noto La Diega, S; Perrone, G; Renna, P (2003). Coordination policies to support decision making in distributed production planning. Robotics and Computer - Integrated Manufacturing. 19 (6), pp. 521-531.

Pujawan, I N. and Kingsman, B. G. (2002). Joint optimisation and timing synchronisation in a buyer supplier inventory system. International Journal of Operations and Quantitative Management 8 (2), pp. 93 - 109.

Thomas, A. S., and Kopczak, L. (2005). From logistics to supply chain management: The path forward in the humanitarian sector. Fritz Institute.

Xu, L. and Beamon, B. (2006). Supply Chain Coordination and Cooperation Mechanisms: An Attribute-Based Approach. Journal of Supply Chain Management, Winter, pp. 4-12

10 PRINCIPLES OF GOOD PRACTICE IN VISION REHABILITATION

11 PRINCIPLES & MODELS OF CHANGE THIS PAPER EXAMINES

145 REVISED 62016 ACCOUNTING PRINCIPLES AND STANDARDS HANDBOOK CHAPTER

Tags: chain management, supply chain, operations, supply, relief, management, chain, disaster, principles

- USECHE 9 EL MITO Y LO FANTÁSTICO COMO REINVENCIÓN

- 30 THE PROMOTION OF ENVIRONMENTAL MANAGEMENT SYSTEM (EMS) DEVELOPMENT

- ÅTERBLICK FRÅN VÅRA 40 ÅR PÅ ULVNÄS EFTER 10

- PROCEDIMIENTO PARA EL INGRESO Y SALIDA DE VEHÍCULOS DE

- BIBLIOGRAFÍA DE ESPIRITUALIDAD AGUSTINIANA ESPIRITUALIDAD (EN GENERAL) ÁLVAREZ LAURENTINO

- KABADAYI FİLMİNE FOTOĞRAFİK BAKIŞ TÜR AKSIYON MACERA

- LEGO ROBOT SOCCER SOFTWARE REQUIREMENT SPECIFICATION IEEE 8301998 A

- MGB FORM NO 062 REPUBLIC OF THE PHILIPPINES DEPARTMENT

- GUIDANCE NOTE TUPE TENDERING COUNCIL CONTRACTS

- PAGE 4 SUR 4 COPIE POUR LECTURE LANCEMENT DU

- 5 ARBEITSVERTRAG FÜR LEITENDE ANGESTELLTE ZWISCHEN …… (NAME DES

- SYLLABUS PHILOSOPHY 570001 SEMINAR IN AMERICAN IDEALISM ROYCE AND

- FINANCIAL INNOVATION AND THE RISKS IT BRINGS REGULATORS MUST

- GLAVA I OPĆE ODREDBE ČLANAK 1 OVIM SE ZAKONOM

- VELYKŲ PRASMĖ PRIEDAS NR 1 MT 28 TUŠČIAS KAPAS

- 2 EL PASADO MIÉRCOLES 9 DE MAYO UN INTEGRANTE

- DISEÑADOR MODELISTA ESCUELA DE MODA MARÍA AGUIAR AVENIDA RIO

- DIVISION OF MEDICAL SERVICES INFORMATION FOR WOMEN YOUR STERILIZATION

- ORTOGRAFÍA COLEGIO TECNICO PROFESIONAL NOCEDAL LA PINTANA CUADRO

- CODE OF COLORADO REGULATIONS 1 CCR 2012 TAXPAYER SERVICE

- REGULAMIN UCZESTNICTWA W PROJEKCIE PN „MAŁOPOLSKA CHMURA EDUKACYJNA W

- REPUBLIKA HRVATSKA POŽEŠKO – SLAVONSKA ŽUPANIJA GRAD KUTJEVO TRG

- 0 PQI 2501 – SÍNTESE E PROJETO DE PROCESSOS

- COMPOSITION ARMY RESERVES AS PART OF THE CZECH ARMED

- AGRUPAMENTO DE ESCOLAS DO VALE DE OVIL NOME DA

- QUE EL CONGRESO DEL ESTADO INDEPENDIENTE LIBRE Y SOBERANO

- GUIDE FOR AUTHORS OF DGINS CONFERENCE PAPERS DR JOHN

- DIRECCIÓN GENERAL DE RELACIONES INTERNACIONALES Y COOPERACIÓN ACADÉMICA FORMATO

- NY VERSJON VEDTAK OM HELSE OG OMSORGSTJENESTER – HELDØGNS

- ORTOGRAFÍA NATURAL YARBITRARIA LA EXISTENCIA DE ESTA VARIEDAD DE

TECHNICKÁ UNIVERZITA V LIBERCI EKONOMICKÁ FAKULTA DIPLOMOVÁ PRÁCE 20112012

TECHNICKÁ UNIVERZITA V LIBERCI EKONOMICKÁ FAKULTA DIPLOMOVÁ PRÁCE 20112012ZAŁĄCZNIK DO UCHWAŁY NR 50620082012 RADY WYDZIAŁU MECHANICZNEGO Z

B LOKOVÝ GRANT FOND PRO NESTÁTNÍ NEZISKOVÉ ORGANIZACE

B LOKOVÝ GRANT FOND PRO NESTÁTNÍ NEZISKOVÉ ORGANIZACETRIBUNAL DE CONTAS DA UNIÃO GABINETE DO MINISTRO AUGUSTO

Sample Commercial Lease Agreement This Lease Agreement is Made

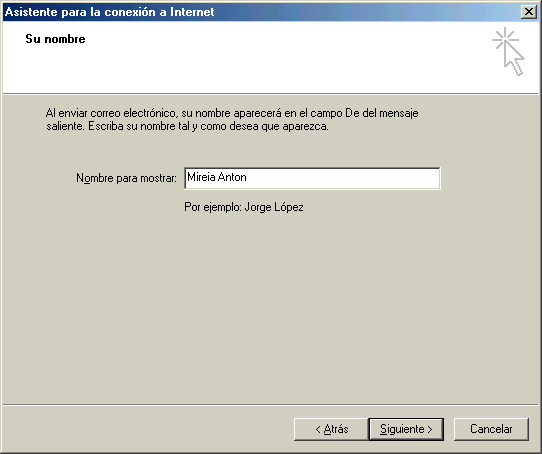

IL·LUSTRE COL·LEGI D’ADVOCATS DE GRANOLLERS CONFIGURACIÓ DEL CORREU ELECTRÒNIC

IL·LUSTRE COL·LEGI D’ADVOCATS DE GRANOLLERS CONFIGURACIÓ DEL CORREU ELECTRÒNIC ECETRANSWP520093 PAGE 7 UNITED NATIONS E ECONOMIC AND SOCIAL

ECETRANSWP520093 PAGE 7 UNITED NATIONS E ECONOMIC AND SOCIALULTIMA REFORMA DECRETO 294 PO 18 5 ABRIL 2014

AVISO PREVIO DEL COMIENZO DE OBRAS (1) (SEGÚN ART

CAA ACCREDITATION APPLICATION AND ANNUAL REPORT SPEECHLANGUAGE PATHOLOGY ACADEMIC

INTERNATIONAL LABOUR ORGANIZATION 15TH ASIA AND THE PACIFIC REGIONAL

INTERNATIONAL LABOUR ORGANIZATION 15TH ASIA AND THE PACIFIC REGIONALNA TEMELJU ČLANKA 25 STATUTA NARODNE KNJIŽNICE I ČITAONICE

ADJUNTO A CÓDIGO DE CCONDUCTA DEL SCAR PARA LA

DRAFT COLLABORATION ON TRAINING COMPONENT FOR COMMUNITY POLICING THE

POSITIVE FOR YOUTH DISCUSSION PAPER MAY 2011 A VISION

POSITIVE FOR YOUTH DISCUSSION PAPER MAY 2011 A VISIONKILKA SŁÓW O NAUCE I MOTYWACJI DO NAUKI W

STUDENT’S NAME 5TH GRADE IDEAL SCORE 20 PTS TOTAL

STUDENT’S NAME 5TH GRADE IDEAL SCORE 20 PTS TOTALDESARROLLO PSICOSOCIAL EN LA INFANCIA TEMPRANA EL DESARROLLO DEL

КЛАСС 8В ДЕНЬ НЕДЕЛИ РАСПИСАНИЕ УЧИТЕЛЬ ТЕМА УРОКА ЭЛЕКТРОННЫЙ

RESOLUCION EXENTA SII N°114 DEL 28 DE OCTUBRE DEL